How confident are you that your water pollution containment system will perform as intended during a critical pollution event?

Ensuring your system works when it matters most requires regular checks, maintenance, and servicing. At Sandfield Penstock Solutions, we specialise in comprehensive Penstock Valve assessments and servicing, helping businesses guarantee their systems’ reliability and compliance.

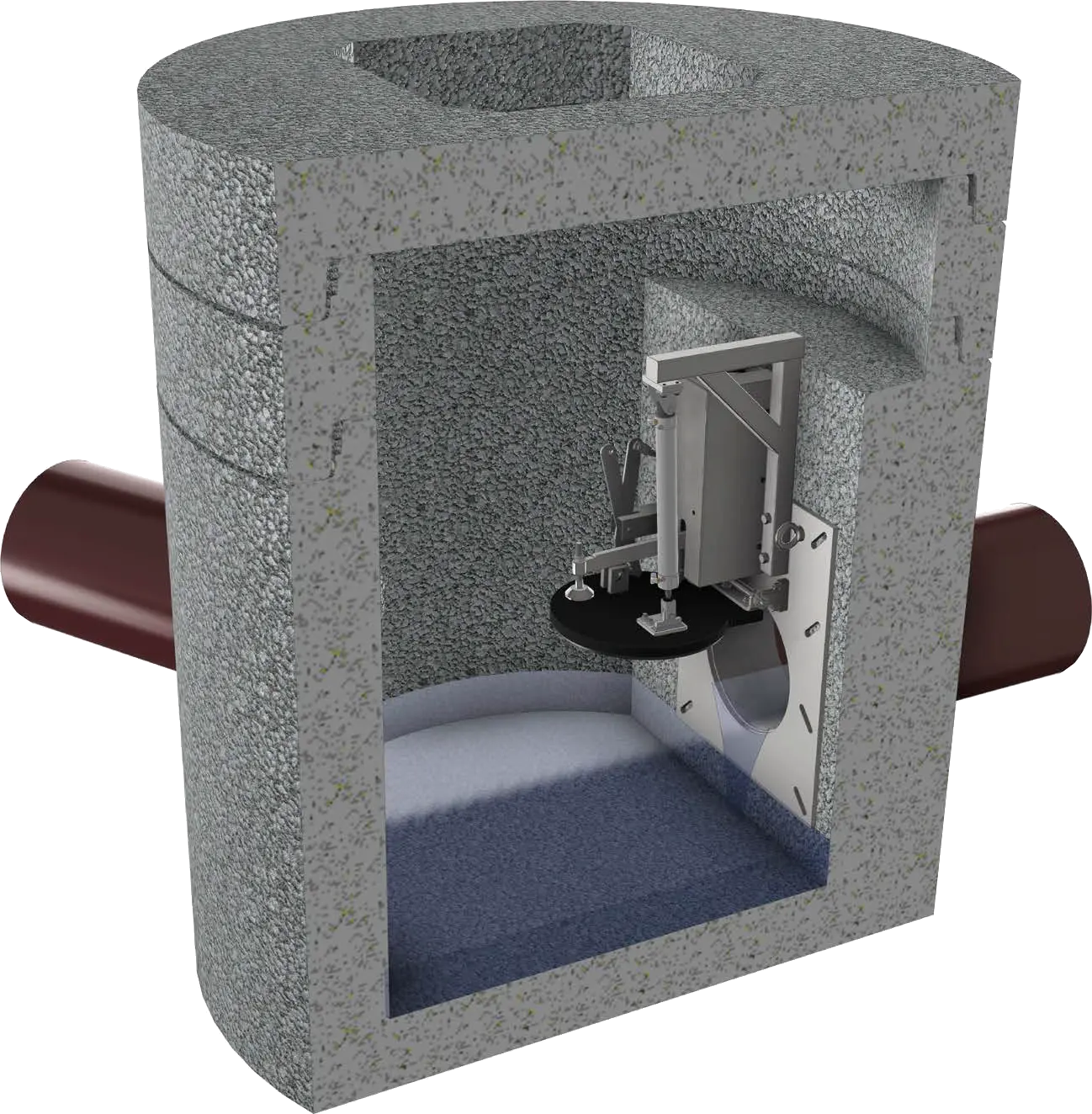

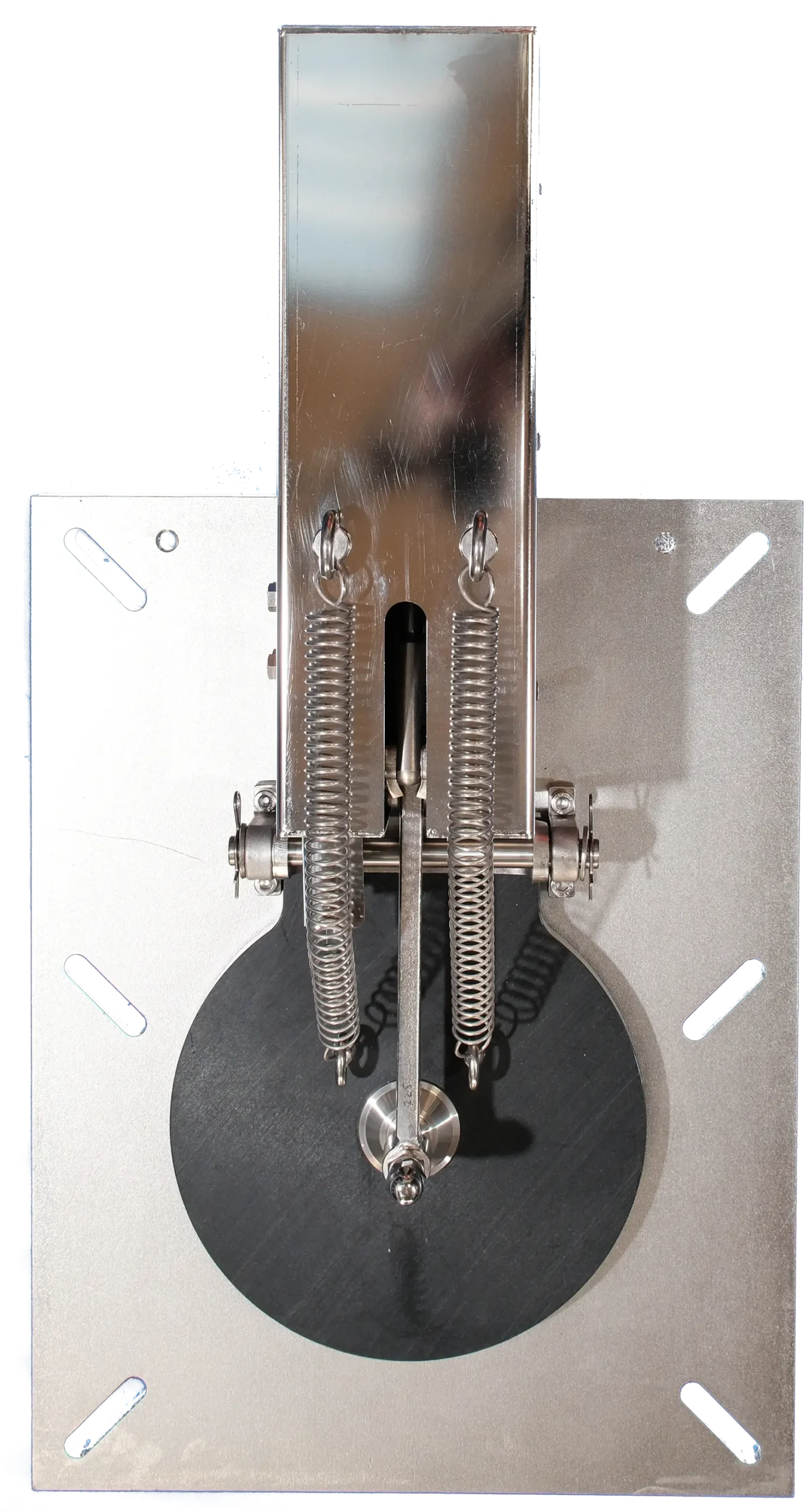

From manual and automatic Penstock valves to non-return valves, flap valves, bladder valves, and other containment devices, we ensure your systems are fully prepared and functioning flawlessly for the moment you need them most.

Preventing pollution isn’t just good practice, it’s the law. Under UK sentencing guidelines for environmental offences, businesses are required to have robust pollution prevention procedures in place. The stakes are high, and fines are based on the revenue of a larger group rather than individual company turnover. For smaller businesses within larger groups, a single spill, fire, or flood could result in catastrophic financial penalties. Industries handling chemicals and additives that pose environmental risks face even greater scrutiny.

Why Is Penstock Valve Servicing Important?

To meet regulatory compliance, including CIRIA C736 and ISO 14001, businesses must demonstrate that their pollution prevention systems are appropriate for the risk, regularly serviced, and functional at the time of an incident. Regular assessments and servicing provide documented proof of system reliability and ensure that your containment devices are up to date with the latest standards.

We understand that many sites rely on legacy systems that were developed prior to the release of updated guidance. Our team helps by assessing your existing valves and containment systems to identify gaps and providing tailored maintenance plans that meet current best practices.

Contact us to ensure your valves meet current regulations.

Common Penstock Valve Issues

Pollution containment devices often fail due to lack of maintenance, damage, or improper installation. Common issues that we resolve, include:

- Valve failure – not stopping flow as intended

- Poor placement – devices located in areas that render them ineffective.

- Accessibility challenges- valves installed in inaccessible chambers or blocked by debris and silt.

- Staff training gaps – teams unaware of device locations or activation procedures.

Our experienced engineers can identify and resolve these issues, restoring confidence in your system’s ability to contain pollution events.

Prevent costly incidents before they occur.

Are you in need of Penstock Valve Servicing?

Also available:

What to expect from a Penstock Valve Service

Sandfield Penstock Solutions provides a comprehensive service for Penstock Valves, tailored to your site. You can expect us to:

Our servicing adheres to CIRIA C736 and is carried out by certified engineers with over 20 years of experience.

Our products

How Often Should You Service Your Penstock Valve?

It is recommended that you implement and document a regular maintenance plan of your water pollution prevention system.

If you are able to conduct weekly or monthly preventative maintenance your system should be serviced every 12 months, in all other cases we recommend six monthly testing and servicing.

If water pollution prevention and CIRIA C736 compliance are on your agenda, we’re here to help. Contact us to discuss Penstock Valve servicing.