Pollution Control Penstock is a difficult term because, personally, I wouldn’t put the word Penstock in the same phrase with the words pollution control. A Penstock Valve is defined as a flow control device. When we talk about pollution control, we’re looking for something that is actually going to stop pollution, not just slow the flow of pollution. The term Pollution Control Penstock is incorrect, its a misnomer.

What is a Pollution Control Penstock?

We really have to look at this in two separate parts. On the one hand we have pollution control, controlling pollution is about having the capability to stop the flow of pollution entirely and usually very quickly. On the other hand we have Penstock Valve’s which are devices designed to control flow, with a built in leak rate and not to stop flow at all.

What is the difference between flow and control?

In normal conditions your drainage system will largely just be handling rainwater, however, rainwater needs to be controlled as too much flow causes turbulence and damage to waterways. In these instances you need a flow control device, a Penstock Valve, to slow the flow into the river so you are not just dumping all of the rain that hits your site into the nearest waterway in a damaging way.

In a pollution situation you have the source, you have the pathway and you have the environment. The source is likely to be an area in the factory where you are handling pollutant material which might get spilt accidentally. The pathway is the route those materials will take to leave the site to get to the environment that needs protecting which includes your drainage system.

If we have an incident on site; it might be a forklift delivering materials which tips over and drops an IBC of Sulphuric Acid which makes its way to the drainage system. In this instance there is absolutely no point having a Penstock Valve slowing the flow because even the smallest amount of Sulphuric Acid finding its way to the environment is going to cause a significant amount of damage. Sulphuric Acid is a good example because it emulsifies, it mixes with water, so the negative effects of a Sulphuric Acid release could be felt several miles along the waterway very quickly. What you absolutely need in this situation is a Pollution Control Device, which is going to stop the flow, prevent the pollutants finding their way to the environment and containing the offending materials so they can be removed responsibly. Essentially, the difference between pollution control and flow is that you are not in control of pollution unless you have the capability of stopping the pollution reaching the environment altogether.

Why do people believe that Penstock Valve’s are the most appropriate device to control water pollution?

The problem is that the term Penstock Valve has been used historically, and in some cases is still being used, by regulators around the world to describe a pollution containment device. What we should remember is that pollution control is a relatively new endeavour and when businesses first started investing in addressing water pollution, as recently as the 1990’s, Penstock Valves were the closest thing they had to what we would now call a pollution containment device. The phrase was picked up universally, has been well marketed by Penstock Valve suppliers and has stuck. The issue now is that we have experienced a number of serious, headline pollution events, we have a more educated market and public, and the technology has moved on, it is just the terminology that hasn’t.

Bringing it back to CIRIA c736 and the Buncefield incident in 2005, the water pollution that happened there happened because the site was relying on Penstock Valves, which had worked well at controlling flow previously, but in the event of the fire they didn’t stop the flow of polluted firewater. The firewater runoff just carried on flowing through, the flow was undoubtedly slowed, but it wasn’t stopped. Buncefield represents a watershed moment in water pollution prevention as it was demonstrated categorically that Penstock Valves are not fit for the purpose of containing pollution.

What is a Penstock Valve actually designed to do in the best instance?

We work with Penstock Valves a lot on sites that need attenuation, to control the flow of water from their premises; they will have limits on the amount of water they are allowed to discharge, including a specific volume and a maximum flow rate, into a waterway and they use Penstock Valves to manage that flow.

You will experience the most common and public example of Penstock Valves on canals. When you look at a Canal Lock what you’ll see is a sluice gate, these Sluice gates are Penstock Valves. You wind them up to allow the water to flow and increase the water level, and wind them down to decrease the flow and lower the water level. What you will notice with a Canal Lock is that the flow never actually stops, there is always some flow passing through it. That is certainly the most commonly known and probably the most correct use of a Penstock Valve, a big heavy, hugely robust device used to control large water flow for decades. Penstock Valves are very hardy devices that work incredibly effectively in extreme environments.

Are their other differences between Penstock Valve’s and Pollution Containment Devices?

Pollution containment devices have been developed, and have evolved, to perform a very specific function, simply to stop the flow of materials offsite in the event of a pollution event, a spill, fire or flood. To perform that function pollution containment devices need to be installed everywhere that fluids leave your site and enter the environment, and to be quickly activated in all of those locations. What we have found is that most often these locations are quite remote from the site so the requirement is to have devices which are easily installed and remotely activated.

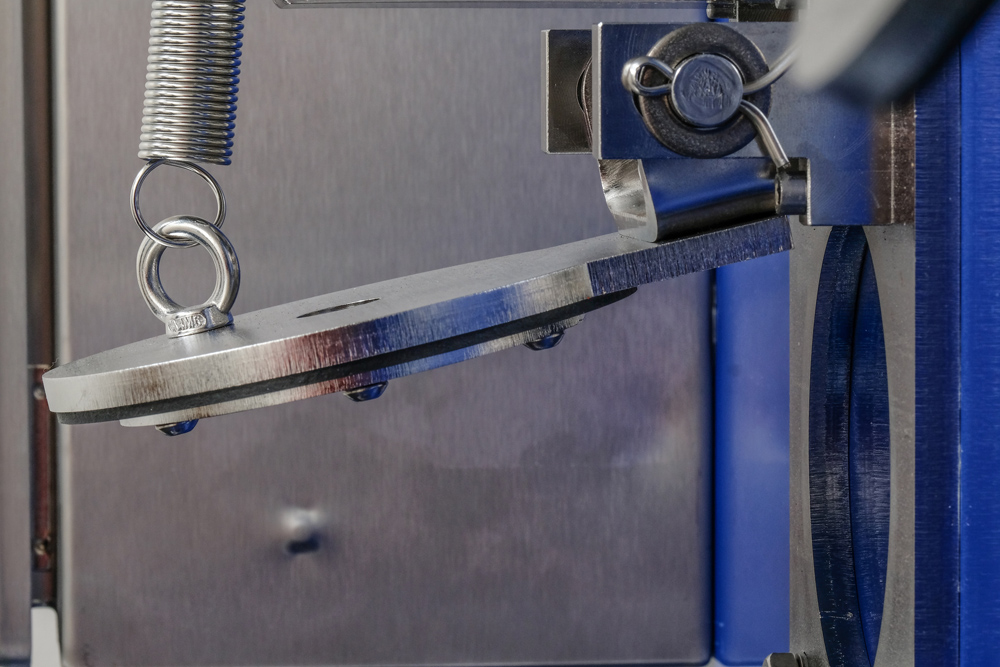

Other than the actual function, stopping flow vs controlling flow, the biggest difference between Penstock Valves and pollution containment devices, like the ToggleBlok that we supply, is their size. Penstock Valves are typically big, heavy duty pieces of kit. If you are using a Penstock Valve to control surface water runoffs you might be looking at a 450 or 600 diameter pipe, that Penstock Valve will be big and heavy. Installing a device on that scale often requires extensive civil works to fit it into a structure like a manhole chamber and cranes to actually get it in. Dedicated pollution valves, such as the ToggleBlok, are fitted without the need of heavy lifting equipment or major remediation work on the chamber. ToggleBlok pollution containment devices are modular, they are comparably lightweight, because they’ve only got one job to do, and that is to sit in a drain or a network allowing flow through unrestricted other than in the event of a pollution event when they must stop the flow immediately.

The size of these devices also effects the amount of power required to activate them. A big, heavy Penstock Valve in constant uses requires a lot more power than a pollution containment device that only requires power when it is activated or transmitting data. The pollution containment devices that we provide typically run on solar which removes the need to run mains power to the device which is a big investment in time and money and hugely disruptive if the valve is a mile away from the site.

This ease of installation is a huge benefit of using a dedicated pollution containment device over a Penstock Valve.

The next difference is about activation. Penstock Valves, exactly like the ones that you see on the canals, are typically manually operated, they require someone to be there to physically open or close them. Now you can imagine a scenario where in a spill, fire or flood somebody has to find and physically activate the Penstock Valves; What if the valves are several hundred metres from the site? What if the operators don’t know where the Penstock Valves are? (this sounds like an exaggeration but we have experienced this on many occasions) What if the operator doesn’t know how to activate the device? What if they forget in the excitement of a flood, spill or fire event? What if there are several of these devices located at the extremities of your site? What if the pollution happens outside of business hours?

If you are serious about preventing water pollution you need to confident that within seconds of the pollution event and the device being triggered that the valve has closed, even if that device is a mile away. Clearly manually operated devices are not sufficient to guard against the risk of water pollution. It is for this reason that we have developed a number of ways that our pollution containment devices can be activated, including remote activation and automated triggering. We typically instal an activation button in the control room or the office at the site which means all somebody has to do is push the button and they will know immediately that all of the devices have been activated and that no fluids are leaving the site. Similarly we have connected our devices to all manner of triggers including fire alarms, pH alarms, oil alarms; we have connected triggers to gates so that the valves are activated if you are taking a delivery of pollutant materials; to jet washing systems if you are cleaning pollutant materials off of vehicles or equipment; and to emergency lighting systems on highways so that the valves are automatically activated in the event of an RTA involving hazardous or pollutant materials.

Some of these events are obvious emergency situations where you would hope that the processes would be in place to guard against causing pollution. Others are everyday happenings that may never be identified as a risk until it’s too late. Manufacturing businesses, like Plating companies that use acids, will have residual loss and should be monitoring the pH discharge of their surface water. If the pH Monitor detects unacceptable levels our dedicated pollution containment devices are activated automatically and the operator is notified and has the opportunity to contain the offending materials and dispose of them responsibly.

Beyond effective and efficient activation of the pollution containment devices businesses will need to provide proof they had sufficient systems in place to guard against a pollution event, if they were to suffer a pollution event and find themselves in court. The devices we supply provide text alerts and reporting on things like maintenance, activations and faults so that if the device weren’t operating as required you would be notified.

How would you go about adapting a Penstock Valve to operate effectively as a pollution control device?

It is certainly the case that Penstock Valves can be adapted to stop a flow, but the question is why would you want to, no matter how much adaptation you invest in you are always going to be putting a square peg in a round hole.

People often look at Penstock Valves for their water pollution prevention because they see them as a much cheaper option than a dedicated pollution containment device. However, they aren’t comparing apples with apples. Part of the problem here is that Penstock Valve is a very generic term, which is perhaps why people specify a pollution control Penstock when they are searching. If you were to search for a Penstock Valve you will get an array of devices ranging in price from a few hundred pounds to tens of thousands of pounds. The temptation is to compare our devices to a six hundred pound Penstock Valve. However, if you adapt a Penstock Valve to the functionality of our devices we estimate that the cost would be in the region of twenty five thousand pounds as compared with the eleven thousand pounds that our devices cost. That is before you factor in the civil costs and disruption of running power to the devices and installing them.

To summarise if you are sourcing a pollution containment device you should expect something that is capable of stopping a flow instantly, easy to instal, easy to activate, easy to maintain and provides you with all of the data you will need as evidence if you are unfortunate enough to find yourself in court defending your actions because you suffered a pollution event.

The valves that we provide are intelligent devices that are connected to the GSM network and will provide you with failsafe pollution containment, very different from a pollution control Penstock, which doesn’t actually exist.