Why Water Containment Should Be A Top Priority On Industrial Sites

Understanding your Legal & Environmental Responsibilities

Whether you’re managing a construction site, factory or industrial facility, one factor remains non-negotiable: effective surface water containment. This is more than your environmental responsibility. As a business, it is a legal requirement.

Many businesses are still unaware that the UK’s Water Resources Act 1991 outlines that it is a criminal offence to “cause or knowingly permit any poisonous, noxious or polluting matter or any solid waste matter to enter any controlled waters.” Yet despite this, water pollution incidents continue to plague industries that fail to implement adequate containment strategies.

Water containment is not just best practice, it’s a legal obligation. Under the UK’s Water Resources Act 1991, allowing pollutants or solid waste into controlled waters is a criminal offence, carrying serious penalties including fines and prosecution. These waters include rivers, streams, lakes, estuaries, and groundwater.

Supporting this legislation is CIRIA C736, a practical guide urging industrial sites to adopt proactive containment measures such as automated systems, defined isolation zones, and emergency planning. TTogether, these frameworks make it clear what’s expected when it comes to following the law and looking after the environment.

The Real-World Consequences of Poor Water Containment

Failing to contain water on industrial sites can have immediate and lasting consequences. Pollutants from spills, leaks, or routine operations can quickly enter watercourses, damaging local ecosystems and creating a threat to public health. The financial fallout; fines, clean-up costs, and legal actions can be severe.

Beyond the monetary impact, businesses risk long-term reputational harm. Regulatory scrutiny intensifies after an incident, and rebuilding trust with stakeholders and communities can take years. Investing in proper containment helps you stay within the law and makes good business sense too.

Common Water Containment Challenges On Industrial Sites

Industrial sites face daily risks that make water containment complex. Routine washdowns and surface cleaning often carry oils and chemicals into drainage systems, while emergencies like chemical spills or firewater runoff add unpredictable threats. Heavy rainfall can also overwhelm under-equipped drainage, leading to contaminated overflow.

Without reliable containment infrastructure and a clear response plan, these common occurrences can escalate into serious environmental and legal issues.

The Evolution of Pollution from Manual to Smart Systems

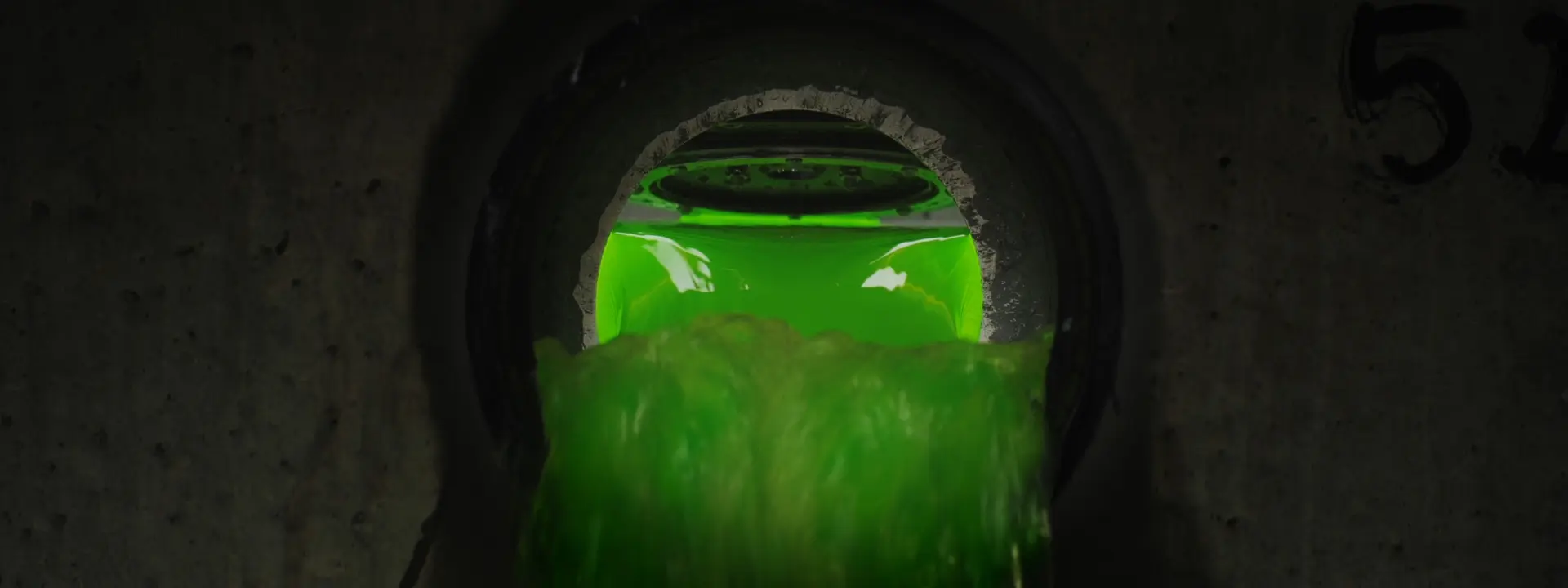

Manual systems like penstock valves have been used for years to contain polluted water, but they rely heavily on people being in the right place at the right time, which can cause delays and mistakes when it matters most. Modern alternatives like ToggleBlok® automate this process, reacting within seconds to prevent spread and damage.

Smart containment represents a shift towards faster, more dependable solutions that reduce reliance on manual interventions and improve environmental safety.

How Smart Water Containment Systems Work

Smart systems continuously monitor site conditions and respond automatically to incidents. ToggleBlok®, for example, uses sensors and triggers to instantly isolate at-risk zones when a spill or overflow is detected. It works with existing infrastructure and reacts to events like fire alarms or storm surges.

This real-time response helps ensure regulatory compliance and minimises the risk of environmental harm, all without the delays posed by manual systems.

Surface Water Management

Effective water management starts with identifying risk zones and installing infrastructure like bunds and retention basins. Regular maintenance and adherence to CIRIA C736 guidelines are essential for keeping systems compliant and ready to respond.

Integrating surface water planning into your overall environmental strategy strengthens your site’s resilience and operational safety.

What Makes ToggleBlok® a Game-Changer?

ToggleBlok® stands out in the realm of water containment technology due to its speed, automation, and adaptability. Unlike traditional systems that rely on manual operation, ToggleBlok® responds instantly to environmental triggers, such as spill alarms, fire detection systems, or weather-related events. This real-time responsiveness significantly reduces the window for contamination to spread, ensuring that hazardous runoff is contained before it reaches drains or watercourses.

In addition to its speed, ToggleBlok® is designed for low maintenance and long-term reliability. It operates autonomously, with remote monitoring capabilities that allow for system checks and diagnostics without disrupting operations. It’s also highly customisable, meaning it can be configured to suit the unique layout and risk profile of virtually any industrial site. For businesses looking to reduce their environmental footprint while enhancing site safety and compliance, ToggleBlok® offers a future-ready solution that sets a new standard in smart containment technology.

Aligning with CIRIA C736 & Compliance Goals

CIRIA C736 calls for more than equipment, it requires preparation. To comply, sites must train staff, document procedures, and regularly test systems. These practices help you stay compliant and prepared for inspections or unexpected incidents

Keeping thorough records and carrying out regular checks shows you’re compliant – and helps maintain trust with regulators while keeping operations running smoothly.

When to Use Penstock Valves and When to Upgrade

Traditional penstock valves may already be installed in low-risk containment areas or as secondary barriers. However, high-risk zones, such as chemical storage or vehicle washdown areas, need smarter, more reliable containment systems

Spill and Stormwater Containment. Are You Prepared?

Without a proper plan in place, even a bit of rain or a small spill can cause serious problems on site. Being prepared means knowing your catchment areas, having the right infrastructure in place, and making sure your equipment is working and regularly tested. Built-in backup, like smart valves and secondary containment zones, adds an extra layer of protection.

When the unexpected hits, a well-prepared site can avoid costly damage and major disruption

How Emergency Water Shut-Off Valves Prevent Catastrophes

In emergencies, timing is critical. Smart shut-off valves isolate hazards in seconds, far faster than manual systems. ToggleBlok® integrates with existing infrastructure and activates automatically in response to danger.

This rapid response protects the environment and ensures that containment efforts start immediately, even if staff are unavailable or delayed.

ROI from Proactive Containment Investments

Proactive containment may require upfront investment, but it pays off quickly. Avoiding fines, reducing downtime, and limiting environmental clean-up costs are just the start. These systems also help lower insurance premiums and support ESG goals.

By protecting your site and demonstrating responsibility, smart containment enhances both operational and reputational value.

Future-Proofing with Smart Technology & Sound Policies

Environmental regulations are tightening. To stay ahead, sites need systems that evolve with changing laws and risks. Smart, scalable solutions like ToggleBlok® allow you to adapt without overhauling infrastructure.

Building in flexibility now ensures long-term compliance and positions your site as a forward-thinking industry leader.

Sandfield Penstock Solutions – Your Partner in Site Safety

At penstocksolutions.co.uk, we don’t just sell products—we deliver tailored water control solutions. Our services include:

- Site audits

- Spill mapping

- System design and engineering

- Installation and staff training

- Ongoing maintenance and upgrades

We’re committed to reducing pollution risks and making sites safer, smarter, and more sustainable.

FAQs on Water Containment for Industrial Sites

Q1: What is the Water Resources Act 1991?

A UK law prohibiting pollution of controlled waters, with serious penalties for breaches.

Q2: Is a manual penstock valve enough?

Not always. Smart systems provide better coverage, especially in high-risk zones.

Q3: How quickly can ToggleBlok® isolate water flow?

Within seconds, which is significantly faster than manual or mechanical alternatives.

Q4: Are smart containment systems difficult to maintain?

No. They’re often remotely monitored and designed for low maintenance.

Q5: Can smart systems integrate with our current setup?

Yes. Most are modular and retrofit-friendly, including ToggleBlok®.

Q6: How can I ensure my site is compliant with CIRIA C736?

Audit your site, install appropriate systems, train your team, and document everything.

Make Containment Your Competitive Advantage

Water containment is no longer optional—it’s an operational necessity. With smarter systems like ToggleBlok®, you can ensure compliance, protect the environment, and build a reputation for responsibility.

Free Webinar | Smarter Water Containment for Safer Sites

Join us for an exclusive session covering:

- How to comply with CIRIA C736

- Avoiding costly pollution incidents

- Live demo of ToggleBlok® in action

Perfect for site managers, health & safety leads, and environmental officers.